Who doesn’t like learning an easier way to do things? These tips all use items around the house or shop, so they won’t cost you a dime. Have your own tip you’d like to share? Send it to MAN@airage.com.

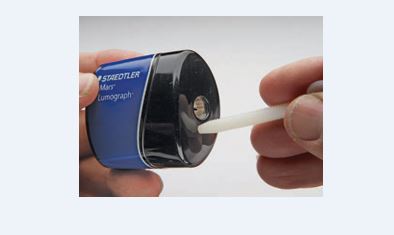

BOLT TAPERING

Are you having difficulty getting the nylon bolts to align with the nuts? This often happens when you try to attach the wing to the fuselage. To solve this issue, add a tapered lead to the end of the bolt using a pencil sharpener. This simple, little lead-in at the end of the bolt will improve the installation and ease of the alignment.

NYLON BOLT EXTRACTOR

This is how to remove a broken nylon wing-mounting bolt at the field. Just heat up the end of a Phillips screwdriver (you can use a lighter or matches, or lay the bit on your car exhaust manifold), and press the screwdriver into the broken stub about ⅛ inch. The heated screwdriver will make a Phillips slot in the broken stud. Once cool, just turn and remove the broken stub.

CONNECTOR CRIMPING

Due to the difference in diameter of standard wires and in sizes of wire from different manufacturers, it is sometimes difficult to get all the strands into the connector before crimping. Use a pair of needle-nose pliers in reverse to open up the connector’s crimping end to accommodate all of the strands. When crimping, this makes for a much neater job and you won’t have to trim off the wild strands.

WING BOLT WRAP-UP

Tired of slipping off your wing bolts and damaging those nice new wings? Wrap narrow strips of masking tape several times around the head of your bolts and then give them a shot of thin CA to harden them. The resulting “fence” will prevent the screwdriver from skidding out of the slot and scarring your wing.

Now THAT’S a fresh new tip; the masking tape on the wing bolts. NICE idea!

Why not just use nylon hex head bolts instead?

The first thing I do on a new kit is to throw away any fastener with a slotted screwdriver head. There are many sources of small fasteners with socket head, button head, and Phillips head screws that you can use as a substitute to eliminate the ‘gonna happen’ damage from using slotted head fasteners.