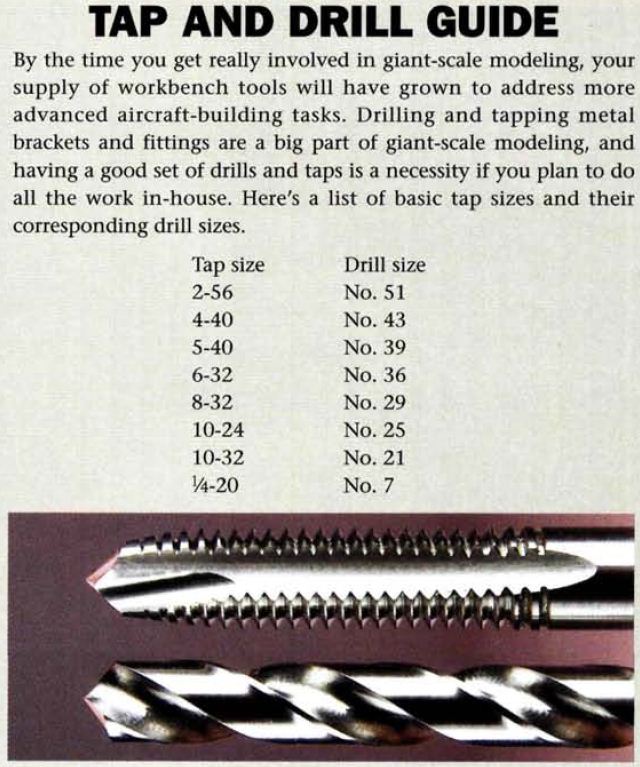

The first few “serious” tasks you learn when you get more involved in the hobby is drilling holes and cutting threads in these holes to accept screws, bolts and other threaded fixtures. Using a tap of the correct “thread-per-inch” is easy enough simply by placing your screw or bolt against the tap. If the threads of both match, then you have the right tool for the job. But figuring out what size hole to drill for the tap and bolt combination is not so easy. For example if you need to tap a hole for a 1/4-20 thread (Very common for wing hold-down screws) the outside diameter of a screw is 1/4 inch and it has 20 threads per inch. The proper inside diameter for this thread is a no. 7 drill or 5/32 (0.156 inch)

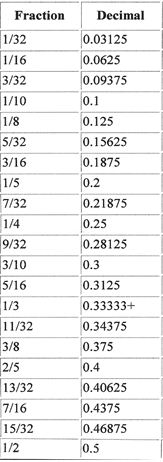

I have included a simple chart here that you can print out and tape to your workshop wall. It has most of the more common drill and tap sizes so you won’t be waiting your time stripping out threaded holes of snapping screws. Also included are common charts for dril and decimal sizes. Hope this helps speed your RC projects.

Check it out! What are you waiting for? Build Something!