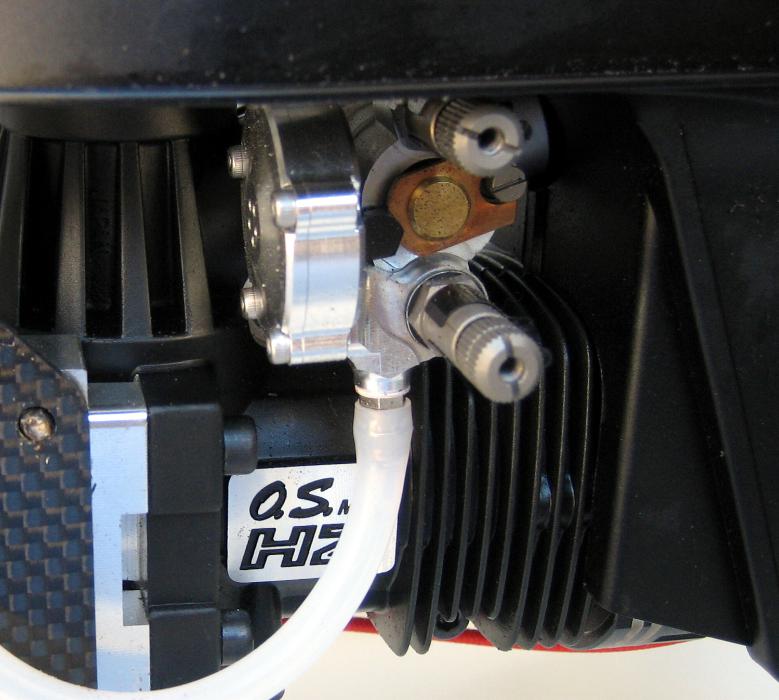

Idle Needle Valve (NV) Adjustment – The photo shows the three needle valves on the OS 90 HZ engine. The main needle valve is on the bottom by the fuel tubing, with the mid-range needle valve on top. The idle adjustment is the one in the center.

Once the main NV is adjusted, it’s now time to adjust the idle NV. To do this, bring the engine to idle, and while holding the rotor head with one hand, pinch the fuel line going to the carburetor. If the idle mixture is correct, the engine should increase in rpm for 2 to 4 seconds and then start to die. If the engine does not accelerate, and starts to die almost immediately, that’s an indication the idle mixture is too lean. Richen the idle mixture by turning the idle needle valve counter-clockwise 1/8 turn, and then repeat the pinch test. However, if the engine accelerates for more than several seconds, that’s an indication the idle mixture is too rich. In this case lean the idle mixture slightly by turning the idle NV clockwise 1/8 turn, and again repeat the pinch test. Of course the acid test of the idle mixture is how the engine performs. A properly set idle NV will allow the engine to slow quickly to a smooth and steady idle, and also accelerate quickly and smoothly. If the engine is slow to come down to an idle, that’s also an indication the idle mixture is too lean. If the engine dies when the throttle is advanced, or is slow to accelerate, that’s another indication the idle mixture is too rich. In either case, make a slight (no more than 1/8 turn) adjustment to the idle NV, and repeat the test. Also, an adjustment to one NV may have a corresponding effect on the other, so repeat this entire process, if needed, to fine tune the mixture at all throttle settings.

We’re almost done. If your carburetor has a mid-range NV, use it to fine tune the transition between idle and full power. When the NV’s are all set, note how many turns it takes to screw each in until lightly seated, then return each to their running position. This will allow you to return each NV to its proper position should you need to remove them for any reason. Also, changes in temperature, humidity, fuel and glow plug will have an affect on the overall performance of the engine and the NV settings.

There is little purpose in adjusting the idle mixture on the test stand since fuel pressure, air-intake volume, and airflow will be different once the engine is installed in the airplane. The idle setting will have to be readjusted again.