Construction of the Das Little Stik began with the wing. This is a 30 year old die cut kit, the quality of the balsa and die cutting was good. If a kit is properly stored in a dry place it can be built many years later.

The building board is as important as the quality of the kit. If the surface you are building on isn’t flat & true don’t expect a warp free airplane. A interior home door laid horizontal across a couple of saw horses will work for a model this size, topped with ½ inch sheetrock or rigid insulation foam. Pin or tape the plans the building board. Protect the plans with wax paper, plastic wrap or the clear backing from monokote.

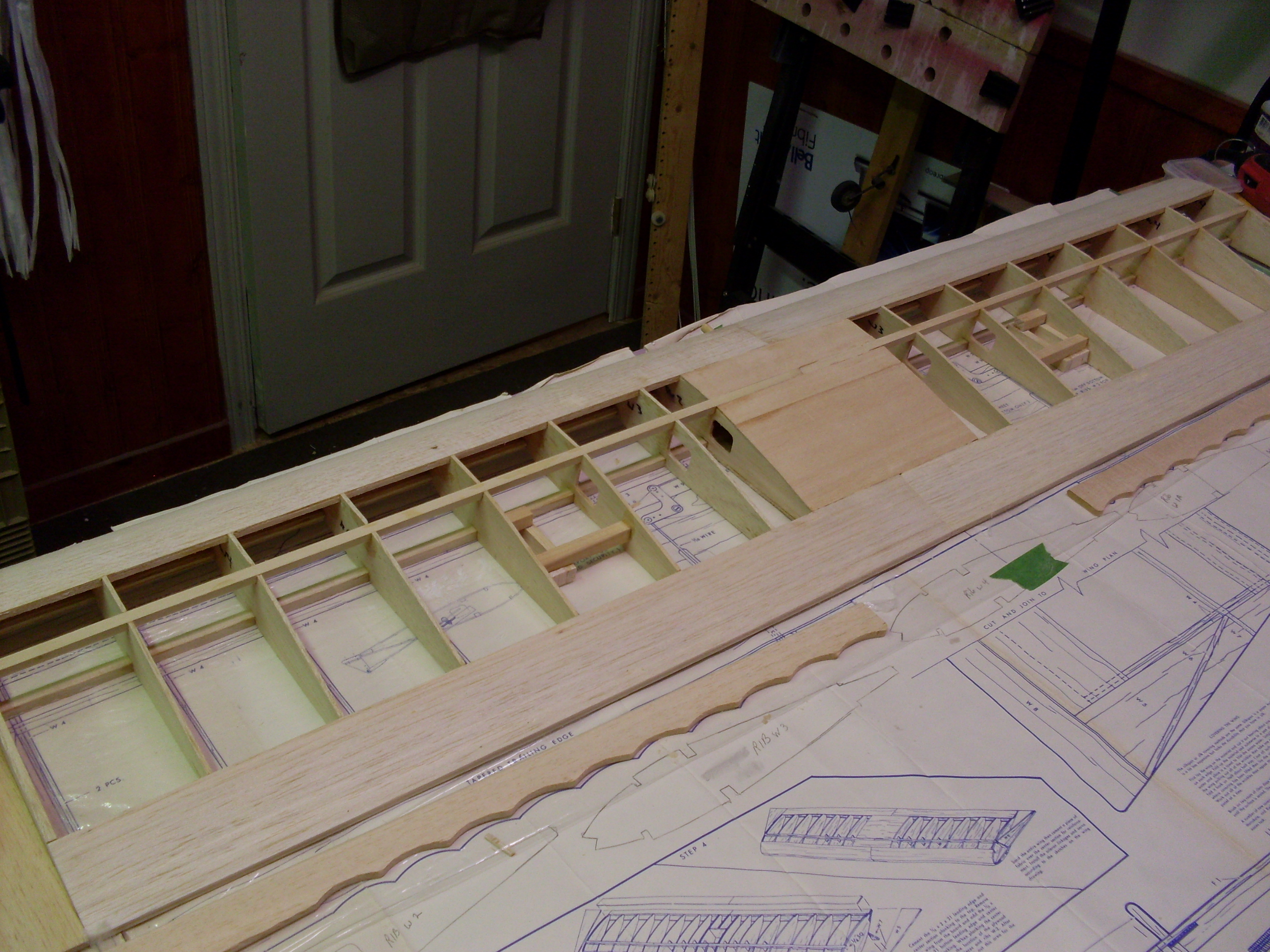

I followed the instructions on the plans for the wing construction, with a few changes along the way. Most of the construction thin CA with slower setting medium used for the sheeting. The wing is built in two halves, beginning with the right. The ribs were removed from the sheeting, using two scrap pieces of ¼ x ¼ the ribs W4 & W3 were stacked then sanded to ensure each had the same shape, the same was done for W1 & W2 ribs. The first change was to replace the balsa spars with ¼ x ¼ pine spars. Follow the instructions for wing construction, however don’t glue W1 into place I also omitted the bell-crank bits as there will be two servos used for ailerons. In this case the wing will have zero dihedral, before gluing the top spar into place use a square to line it up with the bottom spar. Finish the construction of the left wing then build the right, make sure you build a right and left wing.

For a bolt on wing a ¼ in. dowel needs to be installed at the leading edge. Cut two ½ inch balsa blocks 1” x 2.5”, glue the two block together to make a 1”x 1” x 2.5” block. Using the wingtip as a guide mark airfoil shape on side of block, cut out shape, epoxy the block to bottom of wing at the leading edge center. The front of block should be 1/8” aft of leading edge. When the epoxy has cured sand a 1/8” notch into leading edge making it flush with the block. Glue a 1” X 2” 1/8” ply doubler to joining the leading edge & balsa block. Mark the ply doubler for the location of ¼” dowel, center of wing, 3/4” below top edge. Carefully drill ¼” hole in wing, hole should go through ply, balsa block and be a 2” deep, epoxy a 2 ½” dowel into hole leaving ½” protruding.

That’s it for wing construction, next will be the fuselage. This is an older design the wing construction is the most challenging part of the kit.