Many times the control arms as delivered on gas engines are not up to the job. That is, they are too small or wrong shape for the job at hand in getting a pushrod attached to open or close the butterfly valve. This is pretty easy to remedy without getting on the computer and searching thru the RC vendor sites to find something that will work – you can easily make one yourself out of scraps from your grab-bag of parts (I never throw away anything). In this case, I found a G-10 part from something or other that went unused and gave it new life.

G-10 is very solid material and makes a great replacement arm for the choke/throttle control. G-10 is basically just layers of glass cloth laminated with epoxy resin. It can also be made with carbon fiber layers for even more strength. In cases where you cannot find any scrap G-10, it is a good idea to order it by the sheet in various thickness to have on hand for ad-hoc use. Several vendors sell it in fairly small sheets to keep the cost down and make it easy to ship. The G-10 can be hard on band saw blades, you can sometimes see sparks flying when cutting. To save wear on your expensive band saw blades, make as few cuts on the band saw as possible and use your belt or disc sander to do the shaping. A Dremel tool with drum sander works well too. When sanding G-10 made from carbon fiber, be sure to not inhale the dust – it’s pretty nasty stuff.

As a note of clarification and definition, G-10 is what I generally call this material. It actually goes by several names such as FR4, G9, G-10, Glass Epoxy Sheet, Melamine, Phenolic, and possibly more. The differences are from the material used in building and if it is fire rated (i.e., FR4). Phenolic is usually made from paper products vs glass cloth, but is very strong. Whichever material you use, it needs to be of a thickness that won’t twist or flex under use – usually at least 0.032” thick; 0.060” is very suitable. Sheets can be bought in affordable prices and sizes such as 12 inches by 6 inches or larger. One small sheet will last for many projects down the line.

Another note of interest is that G-10 can be used to make custom control horns for ailerons, elevators, and flaps. I’ve even made custom hinges out of G-10! But, be sure to NOT attempt to use standard aircraft plywood to make control horns or throttle arms – it will eventually come apart and you will be very sad when it does fail. I witnessed a very nice giant scale Spitfire fail to recover from a loop and went straight into the Earth! The plywood elevator control horn finally failed and the warbird hit so hard it cracked the 55cc engine cylinder in two! Plane was in pieces. Nothing rebuildable or salvaged. So, take heed on this warning.

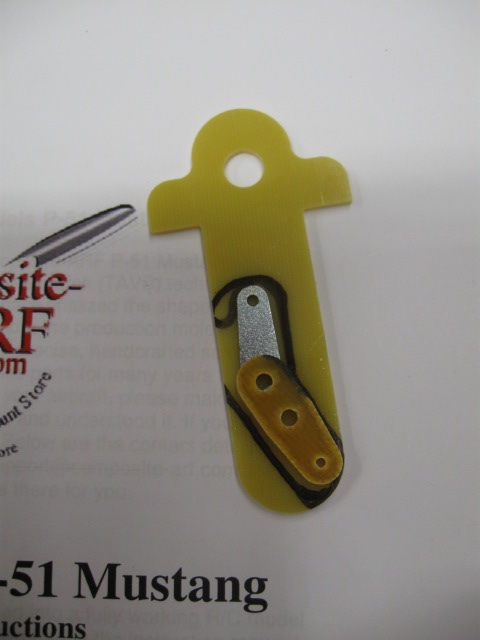

Problem – throttle arm was to the top of carb and I needed it to be at the bottom to get a pushrod on there. Simply flipping the steel arm over would not have given the correct geometry. So, I decided the new part should have an extension to the bottom and a dog-leg offset. I mocked up the desired shape on the scrap G-10 part for the new throttle arm. A couple more scrap parts positioned to form a possible solution.

G-10 is rough-cut along the marked lines.

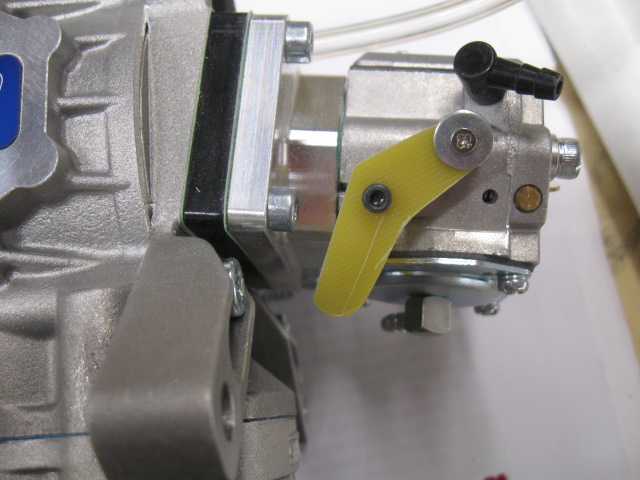

With some sanding and a couple of holes drilled, the new part is tested on the carb. The new, longer, center capscrew is the pivot point and the upper screw secures the G-10 to the factory control arm. New hole for pushrod clevis is yet to be drilled.

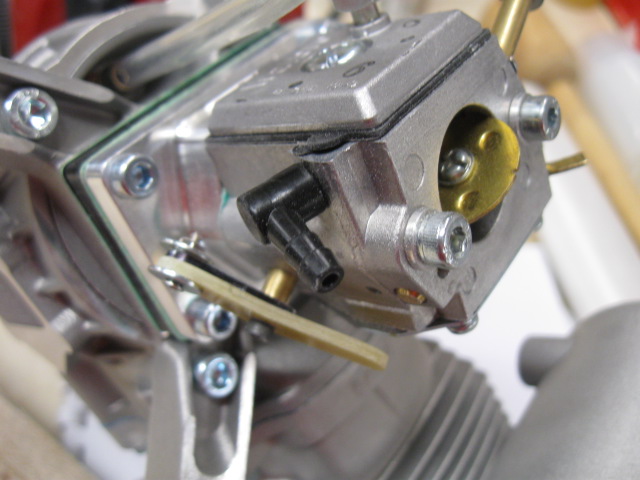

Reverse view of the assembly. The steel factory arm is left in place to anchor the new G-10 part. Note the thickness of the G-10 – very stout.

One more view of the carb assembly with new G-10 arm. Whole job took less than an hour and was basically at no cost.

TEXT & PHOTOS BY LANE CRABTREE

ware can buy this g10 material?

Hi Lenny, you can buy G10 here: https://www.franktiano.com/product-page/g-10-fiberglass-sheets