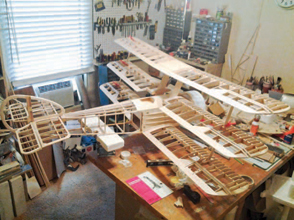

When I built my 1/5-scale Sopwith Triplane, it had rather thin wings. Yes, a low-profile servo, such as Airtronics 94921 or Hitec 77BB, would fit with the shaft vertical, but I had only standard ones on hand, so I went with them. I made an 1/8-inch-thick and 2 7/8-inch-wide plywood plate to fit between the ribs at the servo location and 2 1/2 inches long to go between the main spar and aileron spar. I glued a 3/8-inch-wide strip of 1/4-inch-thick plywood to the inside of the ribs so that I could mount the plate. Use a piece of scrap out of 1/8-inch-thick plywood as a guide to inset the mounts so that the servo plate is flush with the outside surface of the wing. Position the servo on the plate, and mark where the output arm will protrude. Keep the outside edge of the slot 1/2 inch in from the edge of the plate so that nothing will interfere when the plate is in place on the mounting strip. Drill 1/4-inch-diameter holes at each end of the slot, and cut between the holes with a hand-coping saw or power jigsaw. The Dremel jigsaw that I’ve had for years works well.

Building the Sopwith Triplane means that you have six aileron installations. I install my two aileron servos in the bottom wing and then drive the four others about them with slave rods. Keeping the servos in the bottom wing eliminates having to run servo leads up the cabane struts to the top wing.

MODEL AIRPLANE NEWS PREMIUM members can access this article and many others highlighting amazing techniques, RC airplane builds and projects. When you become a member, you’ll get instant online access to our back-issue archives, the latest Model Airplane News Digital Editions, all of our newsstand-only special issues, and much more.

Membership includes exclusive access to our enormous collection of RC information.

- 7+ years of digital editions of Model Airplane News

- Flight Journal and Model Airplane News special issue digital editions, previously only available on newsstands

- Free access to our magazine app through the iTunes Store – get Model Airplane News on your mobile or tablet device

- Contests & giveaways only for members

- 30 years of Model Airplane News archives

- 10 years of Electric Flight archives

- 5% off ALL Air Age Store purchases every time you shop

Why not put the aileron servos in the middle wing? Won’t have to run any wires in struts either. Makes for overall shorter push pull rods, as both top and bottom are connected directly to the aileron, and not from bottom to middle to top. Less slop will result. Just a thought.