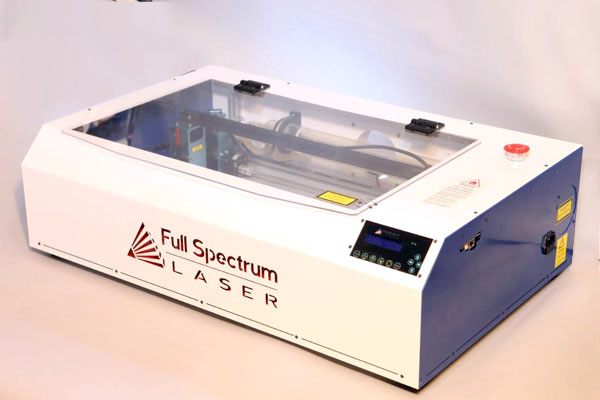

After several years of RC modeling use, the compact laser cutter from Full Spectrum Laser, is still going strong and has been almost completely maintenance free. If you’ve ever wanted to get a laser cutter for your workshop, check out this product review. This easy to use unit is designed especially for hobbyists and small home businesses wanting production quality results. The 5th Gen Hobby Laser Cutter has a 20×12 inch work area and has a glass water-cooled laser tube rated at 40 watts. It is ideal for most RC model builder projects and it has several features that are normally found on more expensive units.

The table-top 5th Gen 20×12 Hobby Laser Cutter & Engaver is the perfect choice for any serious RC model builder.

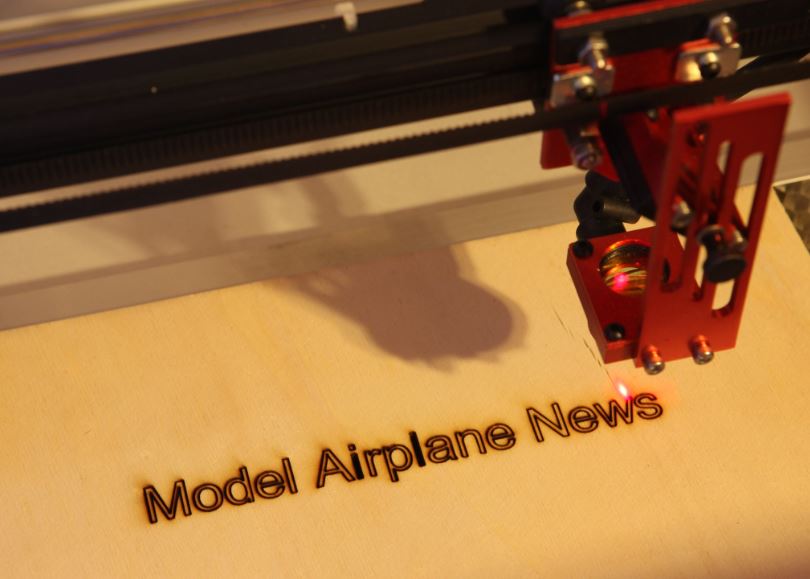

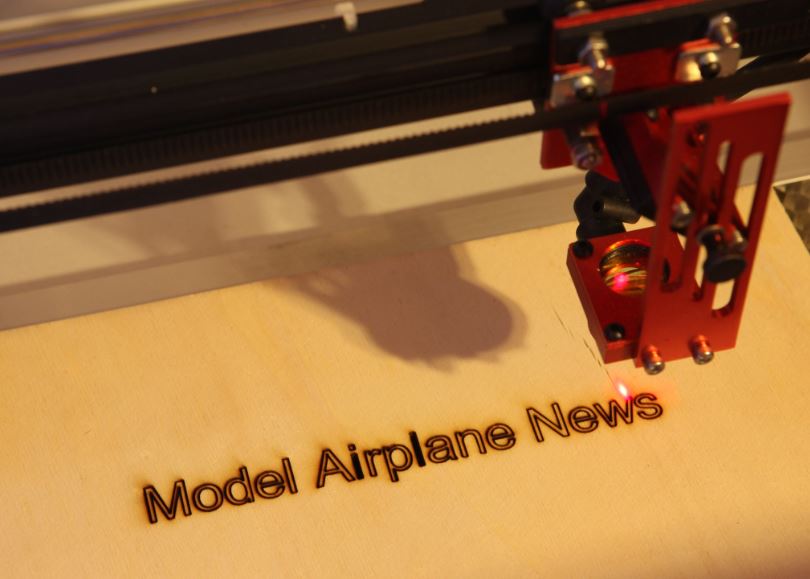

The laser light is invisible so a beam splitter superimposes a red LED marker over the laser, so it can be positioned on the workpiece.

Quality CNC manufactured parts and optics

The 40Watt Hobby Laser is very easy to run and you can control it with any PC or laptop.

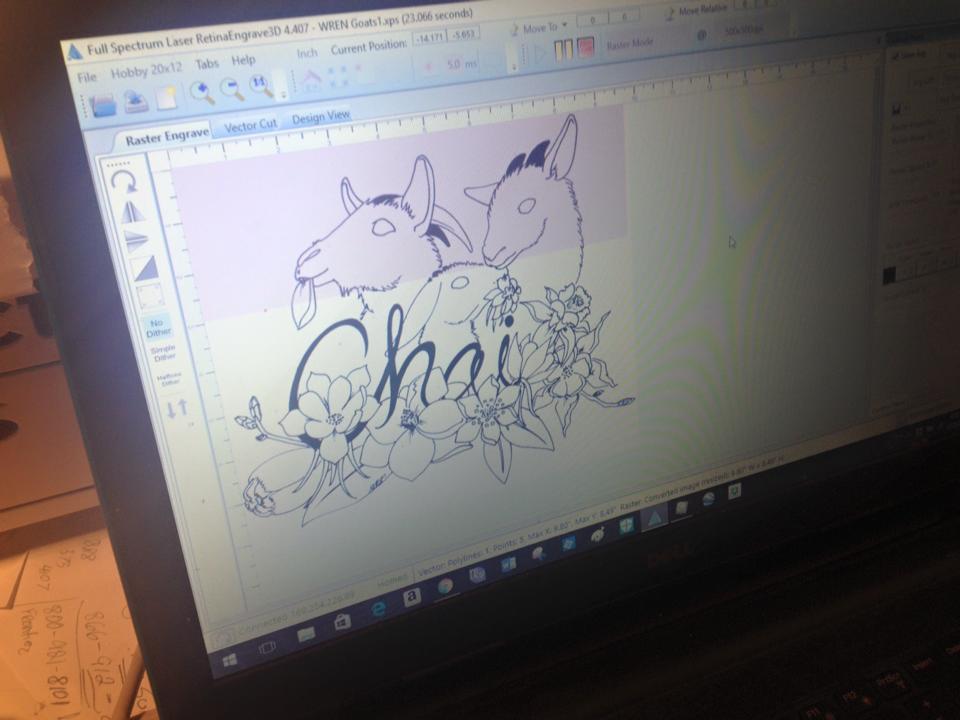

The driver program that controls the laser allows you to “print” you designs directly to the laser using any program that allows printing. That includes CorelDraw, AutoCAD, (or any other CAD program), PhotoShop and even MS Word!

This job was done using Microsoft Word as the program.

Precise and easy to use, the Hobby Laser makes short work of all hobby related materials from Balsa and Lite Ply to birch plywood, fiberglass sheet (G-10) and even cast acrylic material. From cutting model parts to engraving RC event trophies, this 40 watt laser cutter and engraver is perfect for any RC modeler’s workshop.

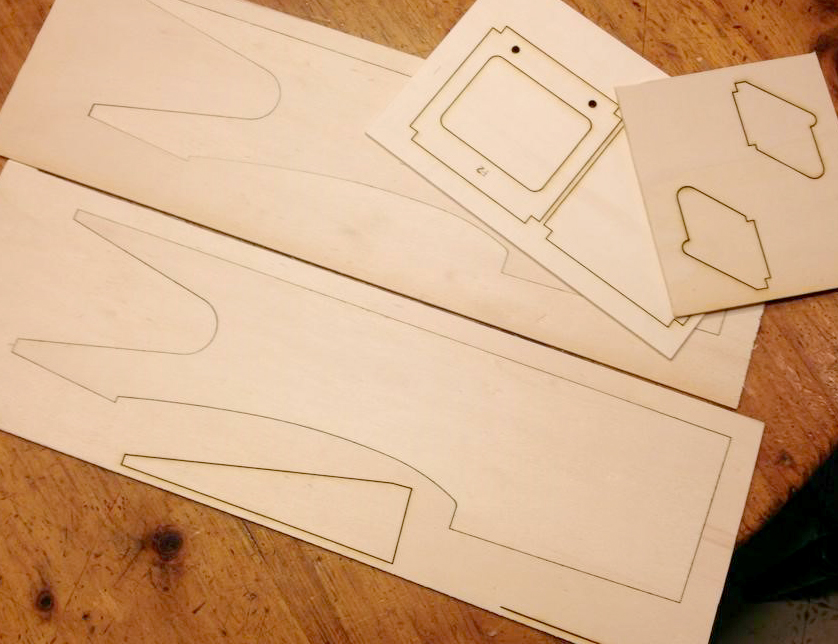

Precision parts cut from all popular RC building materials.

The best thing about this laser cutter is that it is industrial grade and it is manufactured in the USA so there is no problem with service and replacement parts. It is ideal for the serious RC modeler and it is a great first step to starting a home business. Besides laser cutting model parts, you can also engrave trophies, (both wood and acrylic) and it has many accessories to do top shelf laser work like rotary etching on bottles, glasses or other cylindrical parts.

This is the original drawing scan loaded into the laser driver program. It appears in the window and the pink section shows what has already been engraved.

The finished engraving enhanced with water colors applied by hand and brush.

One of several awards made for the Old Rhinbeck Aerodrome Annual RC Jamboree. The plaque is made of Alder wood.

Impressive cast acrylic awards engraved in mirror image on the back to show through to the front of the award.

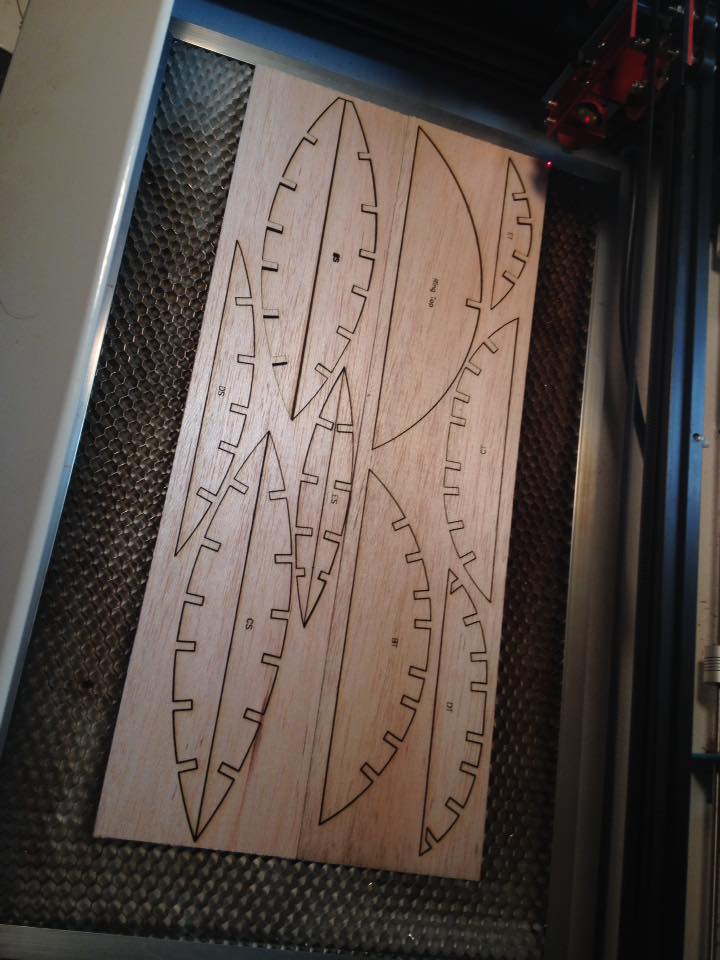

When it comes to building models, what ever you can draw with CAD, can be cut exactly to size.

Identical parts can easily cut and can be positioned to minimize waste material.

Any wood can be engraved, this one is a laminated cutting board intended as a wedding gift.

5 tips for great laser cutting

1. Read all the instructions that come with the laser cutter. You do not want to learn as you go. You can damage the machine if you run the gantry out of the work area. If you can’t figure something out, contact customer service.

2. Never disable any safety features and always wear safety glasses intended for laser use. Make sure all cooling systems are working properly to avoid damaging the laser tube.

3. Make test cuts and keep an operation logbook so you can determine the proper settings and speeds for various materials. This also will give you a baseline so you can judge the performance over time of the laser cutter.

4. Always use the fastest speed and the lowest laser power settings needed to complete the job. All jobs should be completed with one pass. If you use more than one pass, the edges will get over heated and reduce the quality of the cut or engraving.

5. Never cut metal parts or PVC plastic. Metal will reflect the laser and can damage the optics. PVC material produces a corrosive vapor when laser cut, this can damage the optics as well as precision CNC manufactured parts in the laser cutter. Most instruction manuals will show acceptable and unacceptable materials to use.