Good engine performance and reliable starts depend on a properly installed and maintained fuel system.

When you think about it, RC model airplanes rely on two basic systems to fly, the radio system and the power system. Whether you have a nitro burning glow engine or a high octane gasoline sipping power plane, if your engine loses its fuel supply, you’ll find yourself in a dead-stick situation with a plane that wasn’t designed to be a glider. To prevent dead-stick landings, the first steps are taken at the workbench while you install the fuel tank and other necessary fuel-system components. Though this is an easy task for experienced builders, newcomers may find it a bit of a challenge. This article will highlight some of the basics of the fuel components that feed your model’s engine and will make all that plumbing more understandable.

THE BASICS

Just like the family car, the fuel tank contains for the engine’s fuel supply. The tank is connected to the engine’s carburetor with flexible fuel line (plastic tubing), and a rubber stopper seals it. For a tank to operate properly, it must have a vent line that allows air to enter the tank as fuel is drawn out. It relieves the vacuum left in the tank. Model airplanes don’t always fly straight and level. To allow the fuel to flow at different attitudes, the tank has a flexible internal pick-up tube. A heavy “clunk” fitting is attached to the end of the pick-up tube to always keep the end of the tube at the lowest part of the tank. If pickup tube wasn’t flexible, once the fuel level dropped below the pickup tube, the supply of fuel would stop and the engine would die.

Fun Fly airplanes are especially dependant on reliable engine performance.

Lengths of brass tube pass through the tank’s rubber stopper, and the fuel lines that carry the fuel to the engine slip over the ends brass tubes. The rest of the fittings and accessories help the fuel system work properly and make it easier to maintain and operate.

Bad Vibes

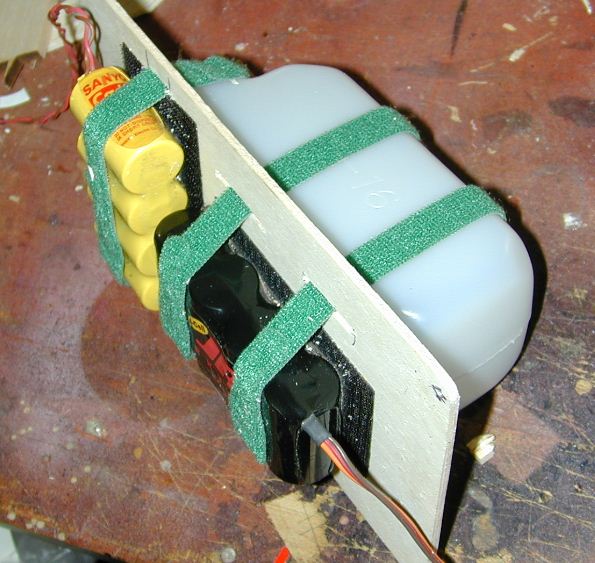

One common problem that can lead to your engine running lean is fuel foaming in the tank. Vibration causes this and it forms tiny bubbles in the fuel. The bubbles cause erratic fuel flow and the air in the bubbles causes the fuel mixture to lean out! The simple solution to this is to make sure to properly pad your fuel tank with soft foam rubber. Also, make sure that after time you check the padding to see if any part of the unprotected tank is coming in contact with the model’s inner structure like a former or engine mount bolt or nut. I prefer to use rubber bands to hold the foam padding in place but you can also use tape. Make sure you don’t compress the foam too much as this will lessen its ability to isolate the tank from the vibration.

Making your fuel tank removable will make it easier to check its condition.

Regular maintenance is key to keeping your entire model in top condition. One way to keep a better eye on your fuel system is to make the tank removable. When there is no fuel tank compartment hatch, I make a slide in tank tray from lite-ply and a matching set of rails inside the fuselage. This way I can slide the tank into place and secure it with a couple of small screws. You can save more space by attaching your battery pack to the tray as well. This system works extremely well especially with larger gasoline powered planes.

Always check your fuel lines for pin holes especially with models that have tight fitting engine cowls.

To choose the correct size fuel tank for your airplane, check your kit’s directions or check the engine manufacturer’s recommendations. You’ll want a tank that can hold enough fuel for a 15 to 20 minutes flight.

HOW MANY LINES?

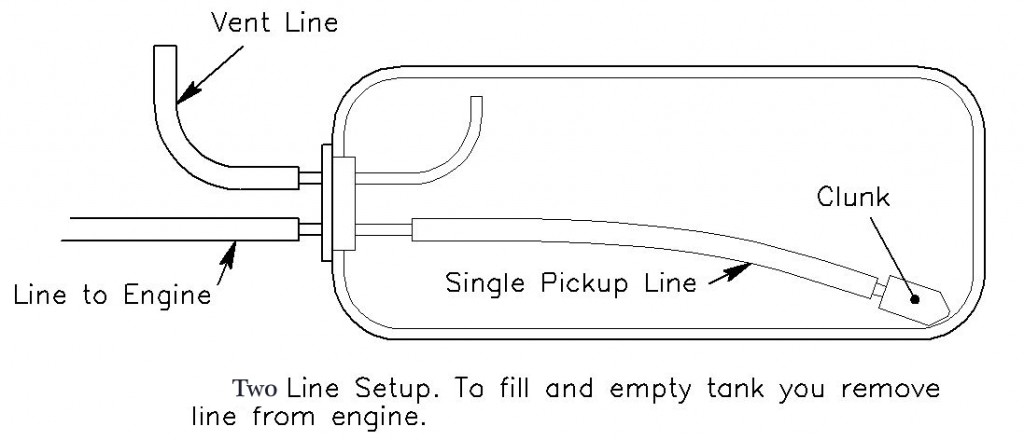

2-LINE SETUP.

A two-line fuel system is the simplest and almost foolproof way to go. The setup requires only two pieces of brass tube, a clunk, a rubber stopper and a short length of silicone tubing. Bend one tube 90-degrees to form the vent and insert it through the stopper. The vent lets outside air in as the fuel is drained out, and it acts as an overflow indicator when you fill the tank. The second tube is the fuel-supply for the engine and the interior pick-up tube and clunk are attached to it. To fill the tank, the fuel supply tubing is removed from the carburetor and attached to your filler pump line. When the tank is full, you simply reattach the line to your carburetor. The vent line is often attached to a pressure fitting on the engine’s muffler. This arrangement helps pressurize the tank to enhance fuel flow to the engine.

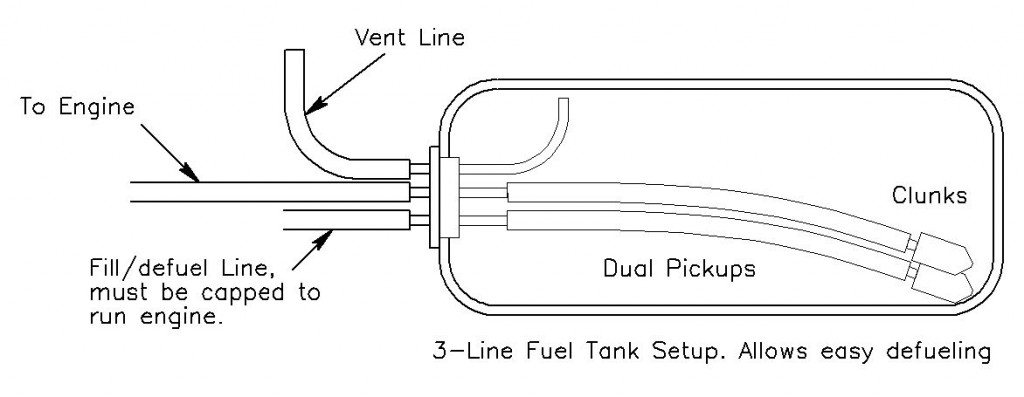

3-LINE SETUP.

In a three-line tank, the setup is just like for a 2-line arrangement, but a third line is added and is used to fill the tank. The third line doesn’t need an interior pick-up line and clunk but many do add them to allow the removal of fuel at the end of the day. Before running your engine, you must seal off or cap the third line to prevent fuel from leaking out. Fuel line plugs called “Fuel Dots” are available commercially to do this but you can also use a tight fitting machine screw or a short piece of 1/8-inch-diameter brass rod material as well. In a pinch, you can use a 1-inch-length of 1/8-inch dowel as well.

GASOLINE FUEL SYSTEMS

The simplest fuel systems are those for gasoline-powered engines. Unlike glow engines, which use a venturi vacuum to draw the fuel into the carburetor, most gas engines use pumper carburetor to draw fuel from the tank. The placement of the tank is not nearly as critical as for glow engines. Also, the gasoline carburetor has a diaphragm pump, which prevents fuel flowing into the engine unless it is running.

T-Fittings are usually used with 2-line fuel tank setups for gas engines. Installed between the Carb and the tank. This makes refueling without disconnecting the line from the carb possible because the pumper Walbro carb does not flood when the fuel is pumped in.

To fill a gasoline tank you can add a T-fitting to the engine’s fuel supply line with an added length of tubing. When you pump fuel into this line, it only flows into the tank and won’t flood the engine. When the tank is full, plug the fill line and the engine draws fuel from the tank. By adding a long fill line and using a Fuel Dot, you can place your “filler cap” anywhere you like, this is great for scale models with large fiberglass cowls that hinder easy access to the fuel lines.

Trouble Shooting

Properly installed, your fuel system will last a very long time and may never need to be changed. In a hard landing, however, some of its parts may be dislodged or a line can become kinked or pinched. Here are some common fuel-flow problems and fixes.

- After a hard landing, the flexible pick-up tube and clunk inside the fuel tank can be forced all the way forward. This can go unnoticed until the next flight when the tank stops delivering fuel to the engine in a nose-high attitude. To prevent this, solder a short piece of brass tube to your clunk. This decreases the pick-up tube’s flexibility a bit but still allows it to draw fuel in normal flying attitudes.

- If your engine starts to run lean for no apparent reason, check for small pinholes in the fuel-supply lines. Check closely where ever there is a tight bend or where the fuel or line comes into contact with the firewall. To help prevent chaffing at the firewall pass-through drill a small hole in the firewall and use a length of brass tube in the holes. Slip the fuel lines over the brass tubes to complete the system.

- If your engine begins to run erratically, debris may have gotten into your fuel system. It usually finds its way into the model’s fuel tank from your fuel storage jug, and if it blocks fuel flow, your engine will die. To prevent this use an in-line fuel filter in the fuel supply line just before the carburetor. Install another filter in your fuel-pump line so you fill your tank with filtered fuel. Add a combination fuel clunk/filter, and you have a triple defense against dead-sticks.

The Best way to keep a reliable fuel flow is to always use clean filtered fuel. Use a quality fuel container and always use inline fuel filters in your model and your main fuel supply lines.

Quality fuel is always the best starting point. Several good brands are available but we have had excellent experience with PowerMaster Fuels. (powermasterfuels.com) They also supply their nitro fuel in metal containers for excellent extended storage.

None of your pictures of models shows a filter in use between the fuel tank and engine.

Failure to install a filter in line between the tank and engine is asking for engine problems.

Another type tank which should be mentioned is the Tettra bladder lined system. These will eliminate fuel foaming issues because there is no way for air to mix with the fuel. There are special cases where these tanks are the only answer to obtaining reliable fuel flow to the engine.

http://www.darrolcady.com/Tettra_Tanks/tettra_tanks.html

FHHuber: Thanks for your comments, you did not see the last sentance of the post? Besides My Hangar 9 PTS Mustang has a filter inside the cowl. I believe it comes that way. Of course you can always find fault if you look hard enough right? :^) And I don’t think the “Tettra bladder lined system” is a common every day Hobby Shop item is it?

To prevent the fuel line in the tank from doubling over and shutting off the fuel flow, put a length of coppee tubing in between the pick up and the flexible tube going to the engine feed line.

I like the idea if using a clunk on the fill line of a 3 line fuel system. I will use this on my next build.

Where can I find a light electric transfer pump? I am building a 108″ Catalina but want to fit small header tanks behind the engines, with a large tank in the hull, well below the carby inlets. The idea is to continuously fill the header tanks, spilling the excess back to the main tank via the header tank breather connections. thus the engines will only see the fuel pressure (ie static head) in the header tanks, until the main tank is empty. Any comments/ideas?

Tim,

I recently built same aircraft and I managed to modify positions of forward firewall to get a14 oz tank

Behind O.S.95 Fourstroke.

Should give plenty of run time as will be able to fly on well under full throttle.

Still to have maiden.

Cheers Phil