After building a Balsa USA Fokker D7 1/4-scale biplane and doing the final setting up on the engine prior to taking to the field, I discovered a violent vibration problem with not one but TWO brand new engines!

Good Results on the Test Stand

I first ran my original engine choice for the D7, a DLE-35RA, on my test stand for just a bit of break-in and to set the needle valves. The engine ran well at all speeds and I was satisfied with the results of the test runs.

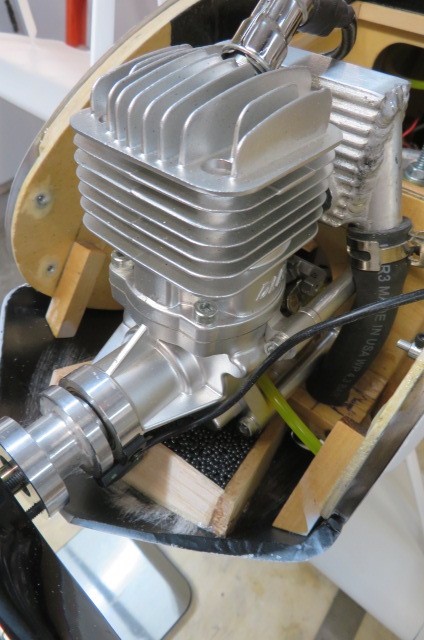

Figure 1. DLE-35RA on the test stand blowing and going! Note the engine is run inverted with the factory DLE muffler. I ran it inverted since at the time I had no alternative muffler for running upright.

Problems Appear Out of the Blue

As the factory muffler was not suitable with the D7 for mounting the engine upright, I bought a J-TEC muffler specially made for the upright mounted engine, bolted it on, and installed the engine on the firewall.

With the D7 build finished and the DLE-35RA mounted and ready to run, it started and idled normally, and all seemed fine until I moved the throttle up to see how she ran in the D7. As I revved it up, around 3,000 – 4,500 RPM, a most violent vibration shook the engine and model almost to death (refer to Figure 2). That RPM range is roughly the “transition point” where the fuel meters between the LOW and HIGH speed needle valves). This anomaly was very hard to digest as I had just recently run the engine on the test stand with great results. At this point, I had considered running the engine a formality; a dress-rehearsal-test of all systems before the maiden flight on the D7 – but nope, no maiden flight happening with this situation! After adjusting needle valves, rebalancing several test props, and looking everything over several times to no avail, I realized a new, unexpected, and hard to explain, problem had come to haunt me.

Figure 2. DLE engine with EXTREME engine vibration at the 3,000 – 4,500 RPM Range! If you were flying with this situation in a full scale aircraft, it would have shaken your fillings out, followed shortly thereafter by the engine parting company with you and your aircraft. With about the same results for an RC model. Ha.

My first thought was there may be a problem with the exhaust extensions I made out of regular automotive heater hose. Due to the relationship between the J-TEC muffler and the standoffs, I was forced to look for a tubing that could be easily curved around and past the standoffs. Refer to the Figure 3 to understand the situation. Perhaps the hoses were a lot less smooth internally than a metal tube and stifling the exhaust flow, thus choking the engine? Let me digress a moment and say that using the heater hoses may sound like a hokey plan, but a fellow RC’er told me he had used them without coming apart for an entire flying season before replacing them. That sounded unusual to me, but as I had no other choices, gave them a try. I could find no vibration problem directly related to the heater hoses as I ran the engine without them and still had the same vibrations at the same RPM range. I now knew this engine must be haunted. Hmmmm. Strange indeed.

Figure 3. DLE-35RA in place. The J-TEC Muffler required some unusual exhaust extensions – 3/4” Heater Hose! But they were not the culprit.

Spare DLE-30 To the Rescue!

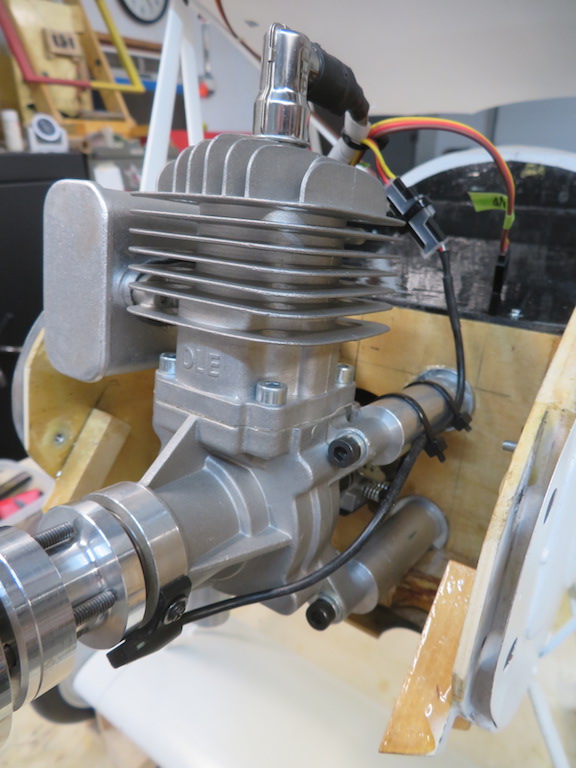

Not to be derailed, I just happened to have on hand a “spare” DLE-30 side exhaust engine, new in box. Surely this brand new engine was going to be free of haunts and strange vibrations. As a bonus, this engine-swap looked promising and fairly straight-forward as the mounting bolt pattern was very nearly the same as the DLE-35RA. The DLE-30 bottom holes were the same and the top holes only slightly narrower. And the DLE-30 factory muffler being a side-mount fit the fuselage well with no heater-hose extensions required. But I needed to change the exhaust tube direction from top-exit to bottom-exit, which required a bit of home machine work and TIG welding by the local weld shop. With the replacement engine and modified muffler installed, it was time to see how she ran. Sadly, almost the same vibration problem presented itself, but not quite as violent as the DLE-35RA. Two haunted engines! This was GETTING VERY STRANGE! What was going on here?

HELP!

I called in help from a fellow RC club member who loves to get involved with strange occurrences like this. I ran the DLE-30 in the driveway for him to witness. He was baffled and after spending at least an hour tinkering with the engine, he said he was outta ideas at the moment. Since the DLE-30 was still mounted in the D7, I gave him the DLE-35RA to take home with him to play with. He checked the ignition unit and timing and even ran the engine at his shop. He didn’t have anything good or bad to report with the 35RA, kind of a wash. So, his report ended any immediate plans for a D7 maiden flight. I decided to concentrate on a few other models I was building.

Perhaps it’s the old Gas Tank?

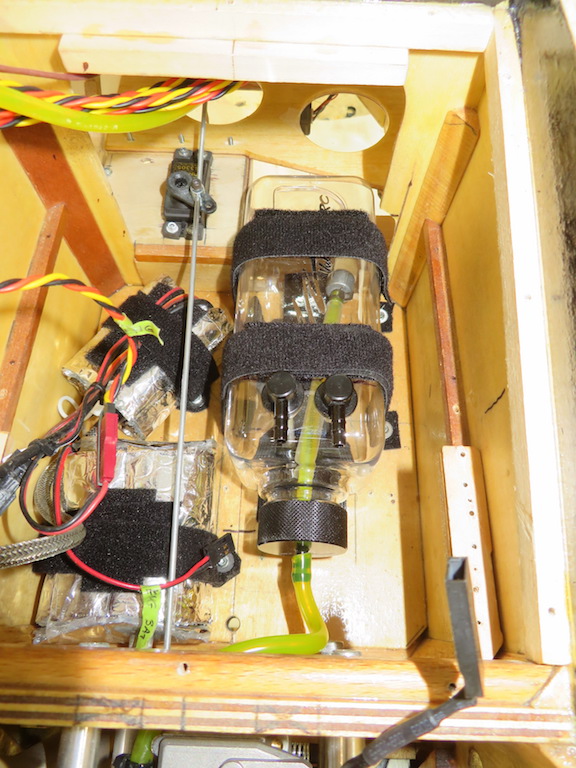

Time passed and I was finished with the other projects and back to the 1/4 D7. Determined NOT to let this engine-vibration-thing ruin the entire build and rob me of a maiden flight, I decided to crawl WAY out on the limb of possibilities! Ha. Thus, at this stage of the game, I didn’t rule out any possibility on what the problem could be. Could the problem be the way gas was coming to the carb through the rube goldberg fuel line setup of an old-school gas tank? This was a long shot, but went with the idea anyway. So, pulled the old-school tank out and replaced with a brand new 16 ounce Valley View 3 line gas tank. After a thorough test run, the new tank functioned properly but had no effect on the vibration problem. But it’s a beautiful tank so I kept it anyway.

Figure 4. Valley View 16 ounce, 3 line gas tank. Great gas tank, but didn’t fix the problem.

One More Try

If it wasn’t the engine itself, muffler, or gas tank related, it MUST be because something in the fuselage structure was weak. I had considered this several times, but always dismissed it as a cause, “Naw, just couldn’t be!” After all, I built the firewall to the plans and used the standoffs that came with the DLE engines. But now, the only thing left was to circle-back and look at the firewall and/or standoffs as the culprits.

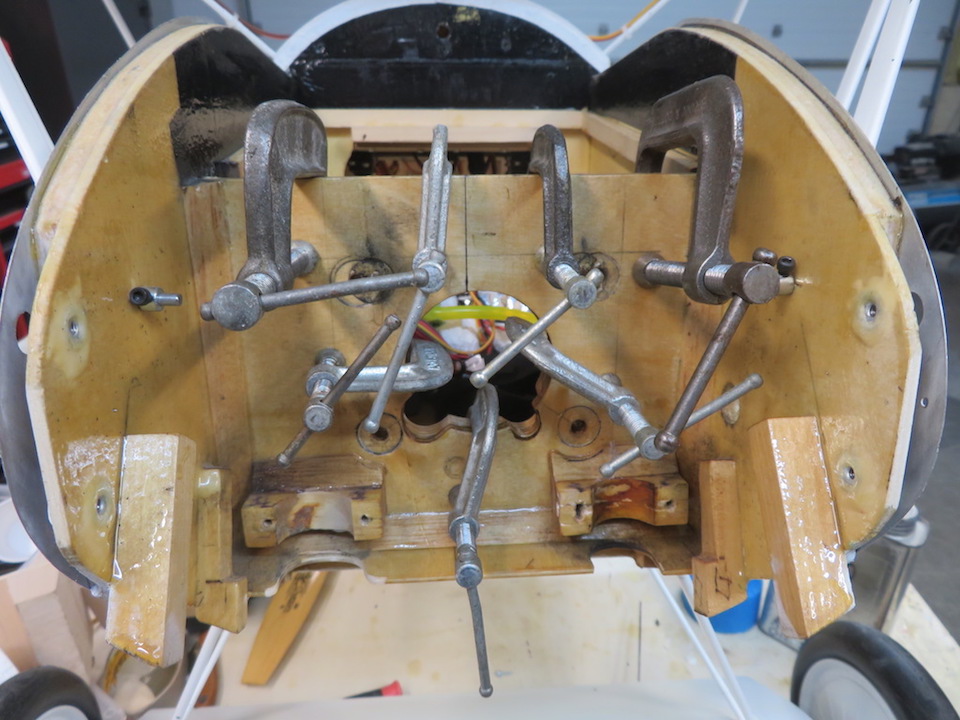

If this avenue of thought was valid, then I must beef-up and add rigidity to the existing firewall, which was made with the precut 1/4” plywood that came with the kit. Now, even this fix presented a problem as I could not simply add a new layer of plywood to the forward side of the firewall, as this would move the engine forward and change the fit and interplay between the engine/muffler and upper/lower cowls, and turn this fix into a HUGE (impossible) rework. Had to keep the solution simple.

Thus, the only practical solution was to add the additional plywood to the AFT of the existing firewall. The few items living AFT of the firewall such as batteries, gas tank, and ignition unit, could be moved back and out-of-the-way just enough to work, but not enough aft to adversely affect the center-of-gravity. So, that was my plan of attack. My initial thought was to use 1/4” plywood to make a full 1/2” thick firewall. But, just so happened that I had an ideal piece of 3/8” aircraft grade plywood, so now I had the makings for a 5/8” firewall – even better! After cutting to the exact size including drilling several holes to match the existing firewall, I lathered-up the firewall and new plywood with 30 minute ZAP Z-Poxy and laminated the dog out of them! Clamped in 7 places and let dry overnight.

Figure 5. I glued the new 3/8” plywood addition behind the existing 1/4” firewall with 30 minute Z-Poxy and clamped her down.

To continue with the idea of greater overall rigidity for the engine, I needed to create beefier standoffs. I went to McMaster-Carr online to find some new raw material. I found the perfect solution – 3/4” 6061 round aluminum bar stock and had them send 24 inches to me. Once in hand, I took the aluminum stock to my machinist neighbor and he lathe-cut them to my specified length (Figure 6). He also drilled 1/8” pilot holes at my request while in the lathe to make sure the holes were straight and true. I had to slightly modify two of the standoffs after I got them home to clear a few spots that slightly interfered with the engine and muffler, but no big effort required.

Figure 6. New DLE-30 Standoffs made from 3/4” 6061 Round Aluminum Bar Stock.

Figure 7. DLE-30 with Beefier Firewall and Standoffs in place and ready to run the engine! Standoffs are a bit of overkill, but so what? They aren’t going to flex ANY! Ha. I used 3.5 inch, 5mm cap screws, all the way thru the standoffs to the Tee Nuts.

Victory at Last!

From IDLE to 6750 RPM not even a burble! Wow! With 20×8 Zinger Prop. Red Line oil mixed 50:1 (3 ounces per gallon). Finally ready for the Maiden Voyage. What a relief!

Figure 8. With upper and lower cowls in place, and safely tied down, DLE-30 engine running at about 4500 RPM and ROCK STEADY! Note how steady the prop hub is (prop hub is not a D7 scale item, but used for ease of repeated starting at home using Sullivan Starter).

A Possible Explanation of the Situation

The LOW/HIGH needle valve transition range I mentioned above is normally WAY smaller (RPM wise) than what it was with the vibration factor caused by the weak firewall. Sometimes before the needle valves are set to perfection, a moment of rough running occurs at this point, usually indicating a too-rich setting. Regardless, the engine(s) should have revved right through that spot with no problem, even with some fine-tuning still being required. But once the slight vibration or burble began, the weak firewall began to vibrate and that vibration was feeding back to the engine thru the flimsy standoffs! Sort of a self-perpetuating monster that grew exponentially! Just take a look at Figure 2 again to imagine how violent the vibration was. And worse, somewhere in the 3000 – 4500 RPM range was likely where she would be cruising once in the air. With continued running at that vibration level, it would have simply been a matter of which was going to fail first – the engine or the model. Even while on the run table, one flying wire on the horizontal tail had snapped from vibration-fatigue at the crimp (I ended up using 2-56 rods to replace the flying wires).

I want to add that in the interest of time and effort, I skipped a step in the true scientific process by assuming that the standoffs were faulty along with the firewall. It may have turned out that just beefing up the firewall without new standoffs would have solved the problem. But, having spent over one year being frustrated by all the problems described above, I wanted to shorten the time to a successful solution by fixing both items at once and moving to a maiden flight sooner. So, I built the new standoffs. But the old standoffs did look a bit wimpy. Ha.

And concerning the firewall design itself. The DVII kit only supported the firewall on three sides (left, right, and bottom), unlike most other aircraft that have 360 degrees of firewall support. By leaving the top of the firewall without support, it leaves open the possibility of flexing under load with just a 1/4” firewall.

And, you may be asking yourself, after finding and fixing the source of the problem, why not return the DLE-35RA back to the model? Ha. Well, that is certainly possible to do, and I may do that. But after TONS of work and COUNTLESS hours to get to this point, I’m interested in first getting a maiden flight with the DLE-30.

Moral of Story

Your firewalls CAN be too flimsy, along with your standoffs, even though they were built and installed to the kit maker’s plans and engine maker’s specs. You may find that technology has improved since the kit you are building was developed. Old-school magneto-engines are not as strong running as the current generation gassers (in my humble, personal, opinion). Thus, for example, running the 30 and 35cc DLE engines may be more powerful than you realize and need more support than what the kit calls for.

TEXT & PHOTOS BY LANE CRABTREE

just read your post on the vibration problem you experienced, found it very interesting, I have a 1/5 scale DVII that I built from Rich Uravitch plans with a Zenoah G38 gas engine for power. The engine is installed in the model but I have yet to start it. Before doing so I will double check the firewall thickness and the mounting bolts holding the engine to it. your article should help me determine if additional stiffening may be necessary.

Personally I would never have mounted a30/35 cc gasoline engine on a 1/4 “ firewall

Another lesson from this story: IF you set up the engine on the test stand EXACTLY as it is set up on the model (same tank, lines, ignition, fuel mix, muffler, stand-offs, etc) and it only vibrates violently on the model, then the only possibility is the model mounting structure itself (i.e. firewall)

I have built a Twin Otter useing a pair of DLE20RA engines.Unless you exactly sync both engines (impossible) the harmonics are outrageous. The noise level from the stock ‘mufflers’ require hearing protection. Got rid of them before they destroyed the airframe.

Very interesting and something to consider when building. Thank you for the insight.

Is either stainless flexible muffler tubing and/or silacone high temp tubing

available and if so what is the source? Thanks