Bracketry is an old term referring to making small brass brackets for scale RC model airplanes. Mostly used for attachment points where you need a solid hard-point for the attachment of wing struts and rigging wires for biplanes and other wire braced airplanes. For the longest time, this was all done by hand, using fine-toothed coping saws and hacksaws, files and more recently, Dremel Moto-Tools with grinding bits and cutoff discs. Once the flat layout part has been cut to shape, it is then sanded and filed smooth, drilled and bent to shape. Well, the newest technique is milling with precision CNC systems and this really speeds the process along.

When you want to make brackets, first you have to figure out what it is going to look like and today we draw with CAD, then print out the drawings and transfer the shape to your brass sheet material.

This is typically 1/16 inch thick (0.0625 in.), and the old fashioned way is to use a dykem layout fluid to coat the metal and use a fine sharp pointed scribe to mark the cut lines. Today however, a wide chisel tip Sharpe marking pen can do the same thing. This process is much more precise than trying to draw with a pencil to draw the cut and trim lines on the shiny surface of brass (or steel,) sheet metal.

With a bench top hobby-grade CNC 3-axis milling machines like the 2-420 from Stepcraft, you can save lots of time and effort after the drawing stage. Depending on the size of your brackets, you select the proper double or single fluted milling bit to produce the parts with great accuracy.

The trick is to figure out the speeds and feeds that work best with your material. As a stating point for this brass cutting job I used a feed rate of about 10mm (3/8 in.) per second with a 0.010 in. depth of cut. I used a 2 mm dual flute “up cut” bit at about 18,000 rpm. This worked fairly good but I increased rpm to about 2,000.

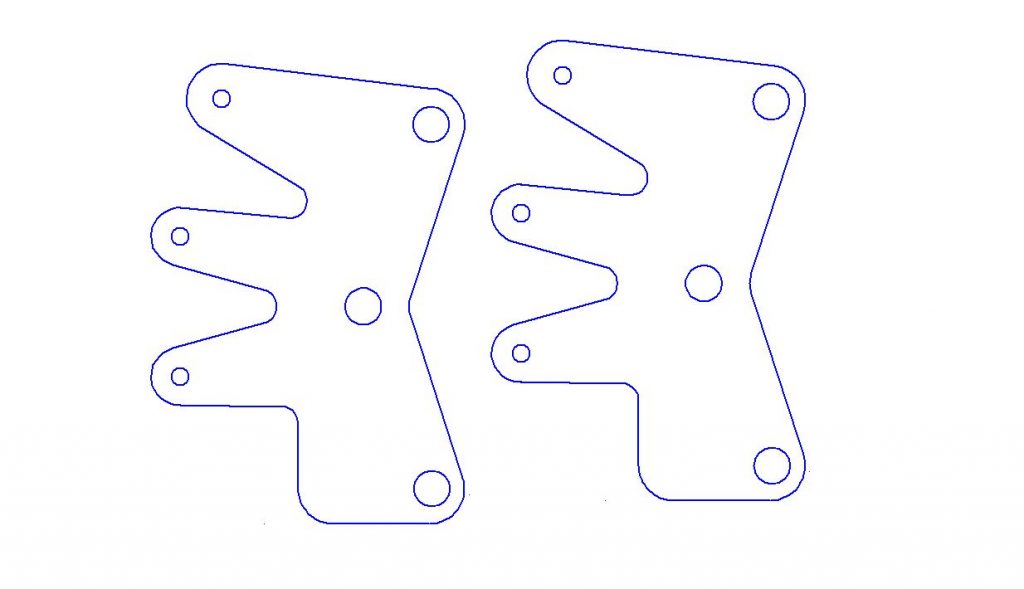

Another good thing about using CAD and CNC is that if you need to make adjustments to your drawing designs and make multiple parts, it is very easy. The old fashioned way is very laborious and time consuming. Above is the final version of the bottom-wing attachment bracket for my Nieuport 24’s V-struts.

Here you can see the final parts cut from the mother sheet of brass material. To keep the parts from flying away after the final cut is made, I use V-Carve Pro to make the G-code that runs my Spetcraft CNC. In the process, I add small thin holding tabs placed around the finished part. When the cutting is complete, I used a fine pair of wire cutters to snip the tabs away, similar to how you would remove molded parts from a plastic airplane kit from its molding trees.

Here you see the finished bracket soldered to an alignment pin made from a length of music wire. The bracket has been bolted in place on the lower wing of the airplane.

The end of the V-strut (made from 1/4 inch poplar), has been drilled to accept the alignment pin. Once everything has been aligned and measured, the pin is epoxied into place in the strut.

The time saving of using CNC to produce brass attachment brackets for any RC airplane is amazing. I would estimate the time spent is one tenth of the old handmade way. Check out the CNC systems online at stepcraft.us.