Whether your goal is to fly big 3D aerobatic planes or to pilot giant-scale warbirds, understanding how gasoline engines operate and how to properly set them up is extremely important. Besides their great fuel efficiency, gas engines are reliable, easy to start and overall are very user-friendly. Like all power systems, however, they need to be installed and set up the right way to keep your plane airborne. Let’s take a closer look at what’s bolted to the firewall.

Getting Started

Gas engines are fairly easy to operate. If you can operate garden equipment and chainsaws, there’s no reason you can’t properly set up and run an RC gasser. Your basic gasoline engine operates using the “fire triangle” principal, meaning it needs air, fuel, and heat to run. Take any one of these away and it will not run. These three fire elements are brought together using the engine’s ignition system, carburetor, and spark plug. I like to install a new engine on a test stand and adjust it before bolting it onto my airplane. It is then much easier to work out the linkages, fuel line attachments, test various propellers and set the top end for maximum power using a tachometer.

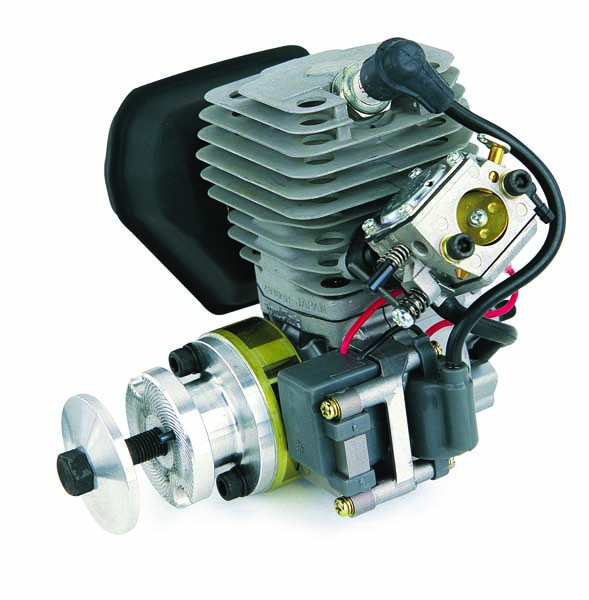

This Zenoah G45 is an older model engine that uses a magneto setup. It’s a workhorse that requires very little maintenance.

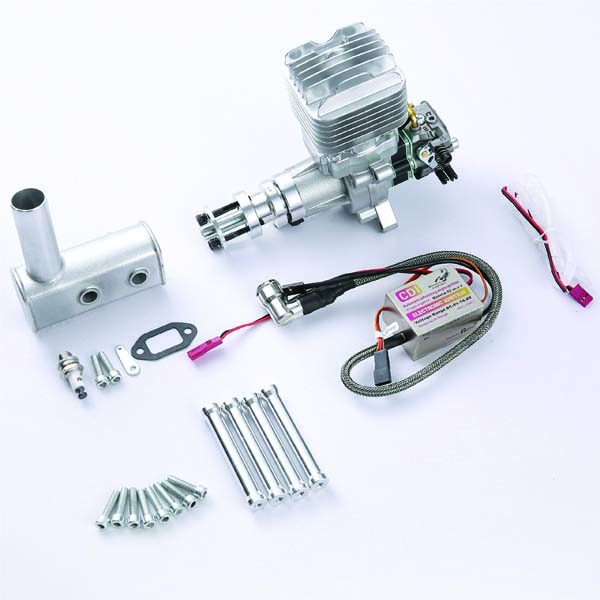

The new breed of smaller gasoline engines, like this RCGF Stinger 10cc side-exhaust powerplant from Legend Hobby, come equipped with electronic ignition systems.

Engine types

Gas engines use either a magneto spark system or an electronic ignition system. Engines that use a magneto setup are a little heavier, but very easy to use and require almost no maintenance. There is no battery required for a magneto, but you do have to install a grounding kill switch to turn the engine off and prevent it from accidentally starting. If you have a helper, always have them carefully handle your airplane and show them where the off switch is. Newer engines with electronic ignition systems are a bit lighter, but they require a separate battery pack and a power switch to operate the engine.

Always have a friend help you start your engine. Securing the model’s tail prevents it from moving forward when the engine fires up.

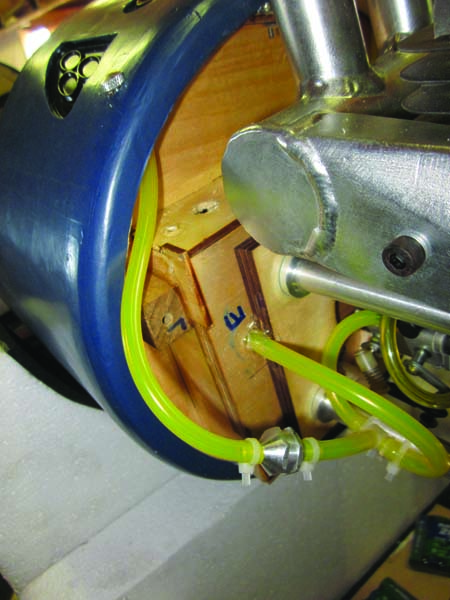

A gas fuel tank with a pickup and vent line, T-fitting for the engine supply line, and a fuel filter.

Startup

When you fire up your engine, the airplane can move forward, so always have a friend secure your airplane before you start the engine. Position the propeller blades (in relation to the magneto magnets or the electronic ignition’s triggering module) as the engine manual suggests. When you swing the propeller through compression, the spark plug should fire. If the blade position is off, it can make starting the engine more difficult. For increased safety, use a proper size electric starter instead of hand-propping the engine. But if you do hand-start it, use a glove or chicken stick.

To prevent debris from clogging your engine, place filters in your fuel container’s pickup line and between the fuel tank and your engine.

Prop care

Always balance your propellers, and if you ever nose over your airplane, check the prop tips for damage. Use the size and pitch recommended for your engine and test-fly using that propeller before trying a different size. After the first few test flights, recheck the prop bolt(s) for tightness. It is always a good idea to do this before your first flight of the day.

Fuel

Regardless of your type or size of gas engine, always use clean, filtered fuel. Install a filter in your fuel container’s pickup line as well as between your engine and the fuel tank. If you use a T-fitting in the engine supply line and a fuel dot for filling and draining your tank, place another filter between the dot and the T-fitting.

It is also very important to properly mix your fuel using the engine manufacturer’s recommended ratio for gasoline and oil. For the first couple of tanks of fuel, use a ratio of 30:1 to 40:1; after that, use 50:1 or whatever the recommendation is. Some more expensive synthetic oils have superior protection qualities and can be used up to a 100:1 mixture, but I have only used regular 2-stroke oil available at most garden supply and hardware stores with excellent results.

FAST FACT

There are 128 ounces in a gallon. For a 30:1 mix ratio, add 4.2 ounces of oil to 1 gallon of gas. For a 50:1 ratio, add 2.56 ounces of oil.

Test Rig

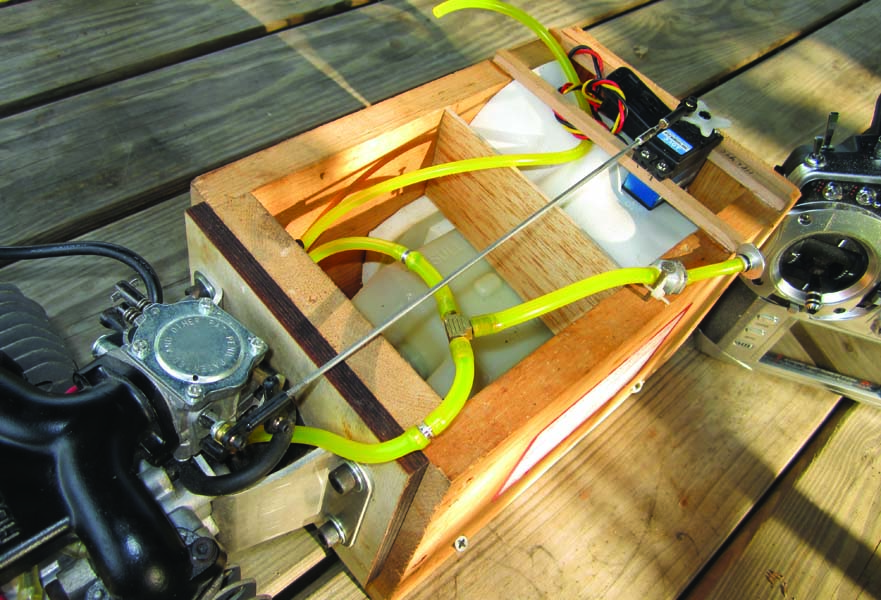

The best arrangement I have found for running gas engines is a simple wood box structure. I make the base from thick plywood or pine with a face (where the engine is attached) that’s the same thickness as the model’s firewall. The face is supported with plywood side pieces glued and screwed together. I then install the engine and screw the structure to a picnic table. I use all the same RC hardware used in my airplane and I install the fuel tank and engine ignition system inside the box. I use a throttle servo and linkage controlled with my transmitter and a receiver or an electronic “servo driver” and battery to adjust the throttle. Getting to know your engine using a test rig is a lot better than trying to figure things out before your first flight at the flying field.

After sorting everything out on the test rig, I then install the engine on my airplane and test run the engine once more with the engine cowl removed. This way I can check the model’s linkage setup, fuel line runs, and the tank’s plumbing for proper function. If it all checks out, you can button it all up, install the cowl, and head to the flying field. You’ll impress all your friends with how easily your engine fires up.

A simple, sturdy box makes a great test rig for setting up gas engines. Notice the throttle servo and linkage used.

After setting up your engine on a test rig, you can install it on your airplane and test run the engine again before installing the engine cowl.

Spark plugs come in different sizes and ratings. Be sure to use the type and size recommended by the engine’s manufacturer.

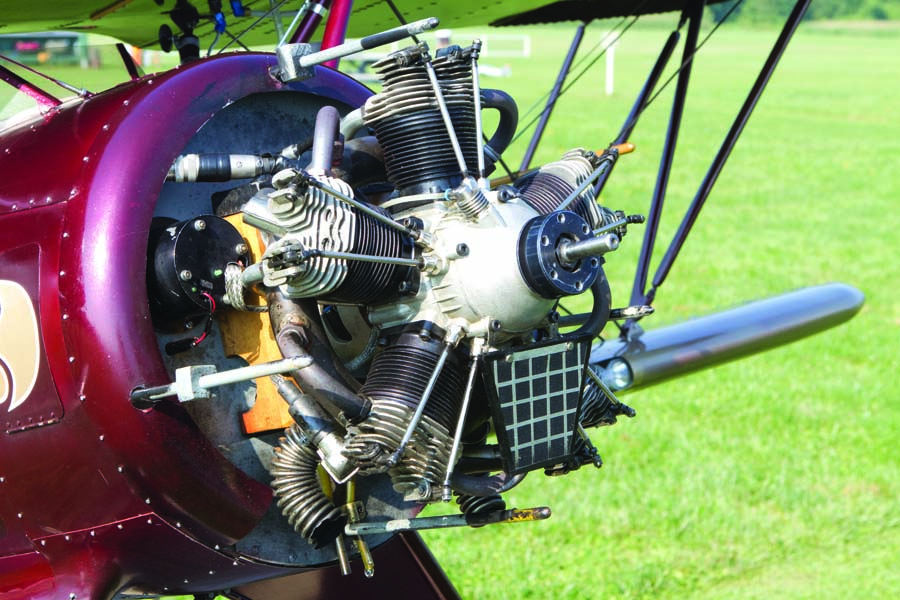

Big and impressive multi-cylinder radial engines are very popular. Most are 4-strokes but they use the same basic setups and procedures to operate. Most use a single carburetor to feed all of the cylinders.

Hand-starting is the norm for most giant-scale modelers. If you do hand-prop your engine, be sure to wear a heavy leather glove for increased finger protection.

Spark Plugs

The spark plug is the heart of the gasoline engine. It used to be very important to use resistor-type plugs to help prevent radio interference that was common with 27 and 72MHz radios. With modern 2.4GHz radio systems this is no longer an issue, but you should use the spark plug recommended for and supplied with the engine. It is also a good idea to check to make sure the spark gap is within specs according to the instructions. Should the gap be too narrow or too wide, it can affect the performance of the engine. A good average setting is between 0.02 and 0.03 inch. Spark gap gauges are readily available at auto part stores and small engine shops.

Needle Settings

When the engine has started, allow it to warm up a minute or two, advance the throttle slowly to full power, and note the response. If the engine sags, loads up and dies, it’s too rich. Lean the low-end needle about 1/8 turn clockwise, and try again. If, however, the engine makes a hollow burbling sound and dies, then the mixture is too lean. Open the needle slightly counterclockwise.

Next, adjust the high-end needle until the rpm peaks out and back off the needle, decreasing rpm by 200 to 300. All engines unload during flight, so don’t try to get every single rev out of your engine on the ground running static. Once you have the high-end needle set, check the low-end setting again, since adjusting either needle can affect previous setting adjustments you’ve made. What you are looking for is a smooth, slightly delayed transition to full throttle and then solid performance without the engine overheating.

Running Radials

Some of the bigger RC giant scale models are now being powered by big 4-stroke, multi-cylinder radial engines. These round engines are very popular but are also affected by engine temperatures. With enclosed engine cowlings, it is advisable to add baffles between the cylinders to channel the incoming airflow directed through the cylinders’ cooling fins. This setup helps you to maintain the recommended rule of using “two times the cooling air exit area relative to the air inlet area.” It is a small detail but very important for a properly running engine. In operation, use the starting procedures (and the fuel mix ratio) recommended by the manufacturer.

Bottom line

Gasoline engines, if properly installed and taken care of, are the most user-friendly power systems available. They are easy to start, fuel efficient, and reliable. After you’ve set up your carburetor, you usually won’t have to readjust it for an entire flying season. And remember it’s no secret: a properly running engine will greatly extend your RC airplane’s lifespan!

TROUBLESHOOTING CHECK LIST

If you have difficulty starting and obtaining a smooth transition from idle to full power, here are some common items to check off your troubleshooting list.

– Does your engine fire up, burn off the prime and then die?

Check your fuel draw. Make sure the fuel lines are not pinched, kinked, blocked or have any pinholes. Make sure your engine is properly set up. Is your fuel tank installed upside-down? It happens to the best of us. When you flip the prop (with the choke closed), the carburetor should draw fuel and you should be able to see it move in the fuel lines toward the carburetor.

– The carburetor doesn’t draw fuel.

Check the needle valves for proper settings. Make sure the carburetor is tightly fastened to the engine and is not leaking air. Check the carburetor’s internal fuel intake screen filter and make sure it is clean. It is under the carburetor’s top cap (the one held in place with a single screw). If it’s dirty, remove it and flush it with fresh gas or replace it. Finally, check that the engine head/cylinder case is tightly fastened to the engine case and that the gasket is undamaged. Even a small air leak here can affect compression and prevent the engine from starting.

– There’s no spark.

Make sure your kill (grounding) switch is in the correct (run) position. If you are using an electronic ignition, make sure the battery is fully charged and the wiring to the timing sensor is properly connected.

– An engine that has been running well loses compression.

Check for a stuck or broken piston ring. If this happens during flight, perform an emergency landing as soon as you can. Don’t turn the engine over by hand as this can easily score or gouge the piston sleeve. Carefully check for internal damage. If you don’t feel comfortable doing it yourself, send the engine out for inspection and repair.

By Gerry Yarrish

Good well written article, would be good to get one on how to effectivelly silence gas engines as with the supplied mufflers they are not suitable for many flying sites.