The Stepcraft-2 420 CNC desktop system is more than just a one trick pony. The system is designed to accept a whole range of additional attachments for doing precision operations in a variety of ways. I just tried out the Drag Knife attachment and I have to say it works like a charm.

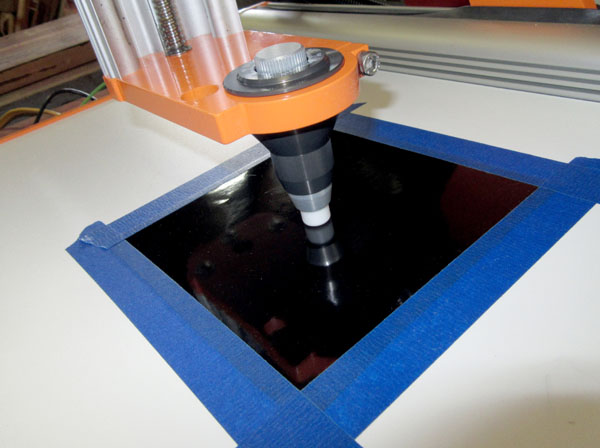

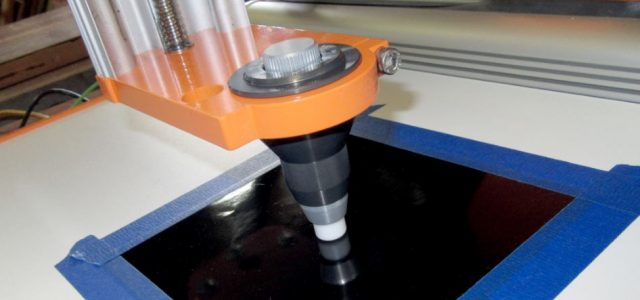

Removing the power spindle and replacing it with the drag knife attachment is as easy as loosing and tightening a single screw. The attachment has a nylon end cap with a hole in the center that houses the very fine drag knife. This knife is supported by a small swivel bearing for very smooth and precise operation.It simply slides into place and is held by the bearing.

Removing the power spindle and replacing it with the drag knife attachment is as easy as loosing and tightening a single screw. The attachment has a nylon end cap with a hole in the center that houses the very fine drag knife. This knife is supported by a small swivel bearing for very smooth and precise operation.It simply slides into place and is held by the bearing.

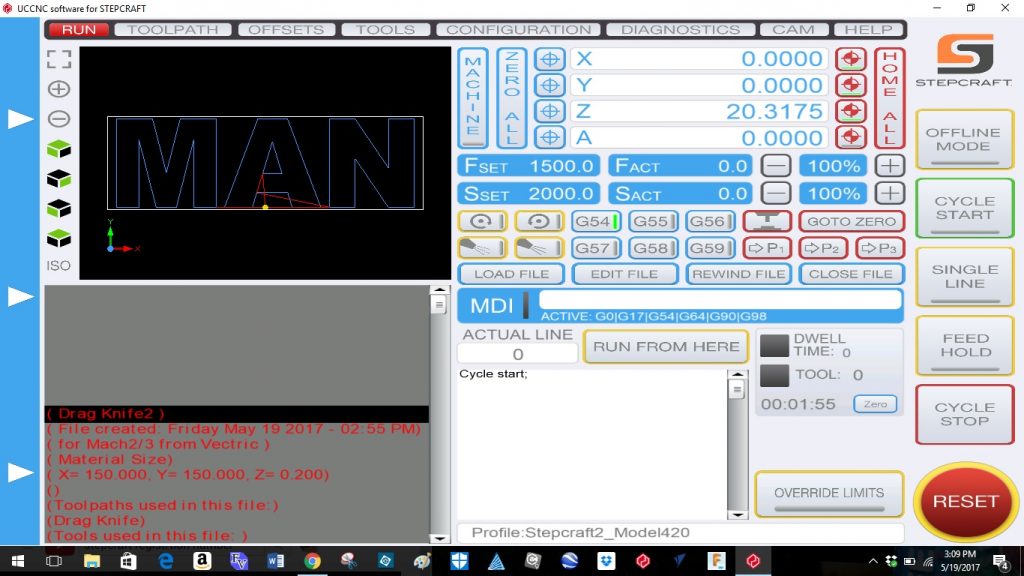

(Above) Here’s the UCCNC program dashboard with the “MAN” drag knife tool path preview in the upper left corner.

To operate the system as a vinyl cutter, all you have to do is setup the UCCNC drive control program just like you would to run an end mill. You create the job with a program that produces the required G-code, (I used V-Carve Pro), and input the proper dimensions and setting for the job. Since the attachment is spring loaded, this requires a cut depth of about 2 to 3mm (1/8 inch), so when the knife is cutting the CNC lowers the tool slightly to keep it under spring tension. You input the g-code as you would for all jobs, then zero all the axis and enter the new job zero position. Next the Z axis is set so the knife just touches the top of your vinyl material.

Before you install the attachment in the tool holder, you first have to set the knife cut depth and this is easily done with the top indicator dial. Install the knife in the end of the attachment, and adjust the dial so the blade just barely protrudes from the plastic end cap. You can check the depth of cut by pushing the attachment gently on top of a piece of test vinyl and drag it. Inspect the vinyl and see if it has been cut. If the knife cuts all the way through the paper backing, you have to retract the knife for a shallower cut. When properly adjusted the drag knife will cleanly cut through the vinyl but will only crease the paper backing.

I made a simply “MAN” job and produced the g-code for the job, I then taped a piece of stick-on vinyl to the work surface with some blue painter’s tape.

I made a simply “MAN” job and produced the g-code for the job, I then taped a piece of stick-on vinyl to the work surface with some blue painter’s tape.

To zero out the Z-axis I moved the cutter over the middle of the test material and used a piece of paper while lowering drag knife manually until it just touched the paper.

When I ran the job cycle, it took less than a minute to complete the job. I then used a hobby knife to “weed” away the waster material leaving my letters cleanly cut and attached to the backing paper.

If you ever wanted a custom vinyl cutting machine, the Stepcraft CNC desktop system does a great job for any size letters or designs you care to make, (within the limits of the size CNC system you have. Give it a try, you can make all sorts of custom airplane markings, signage, decals, etc. Your imagination is your only limit.

If you ever wanted a custom vinyl cutting machine, the Stepcraft CNC desktop system does a great job for any size letters or designs you care to make, (within the limits of the size CNC system you have. Give it a try, you can make all sorts of custom airplane markings, signage, decals, etc. Your imagination is your only limit.

To apply the new vinyl letters to you model, all you have to do is use a strip of tape to lift them off the backing paper and position them on the model.

Here the “MAN” graphics have been applied to the Sonic model. Suitable vinyl stick-on material is available online on Amazon and craft stores like Michaels.

Gerry,

Quick question. Can MonoKote or UltraCote be substituted for vinyl? TIA!

Rick